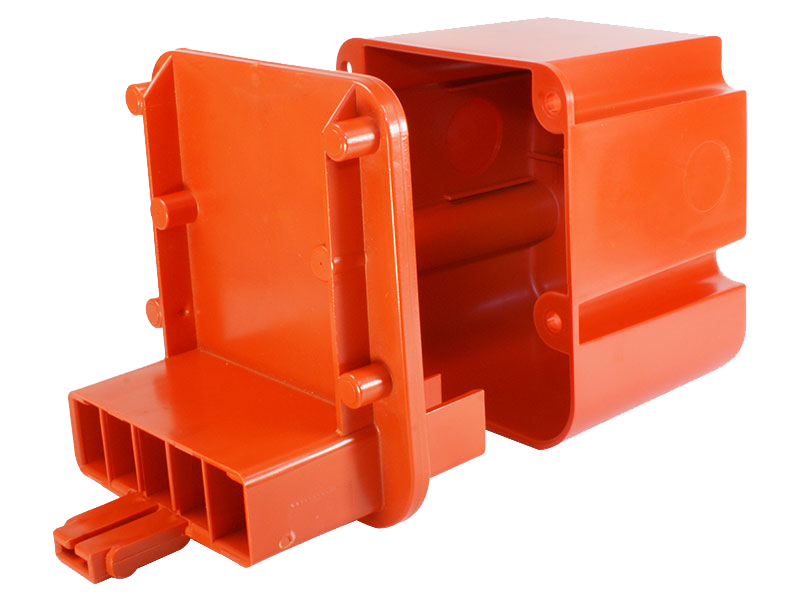

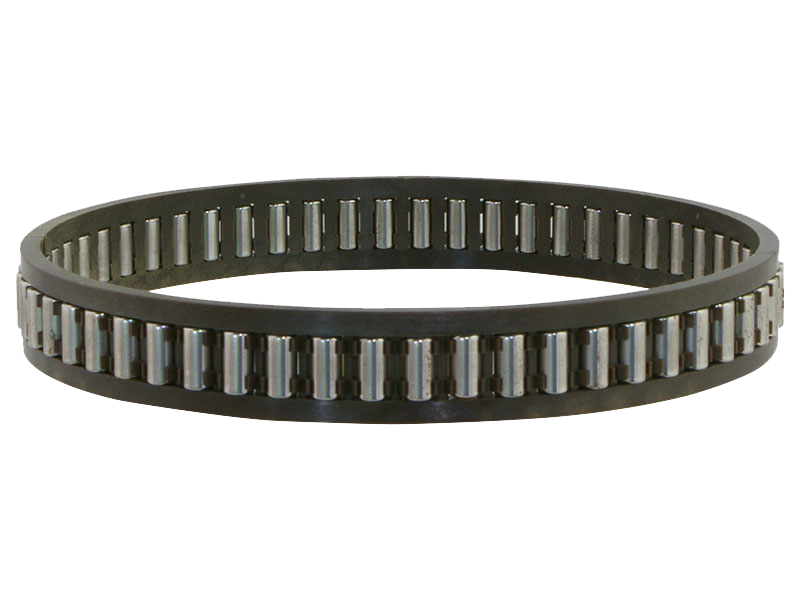

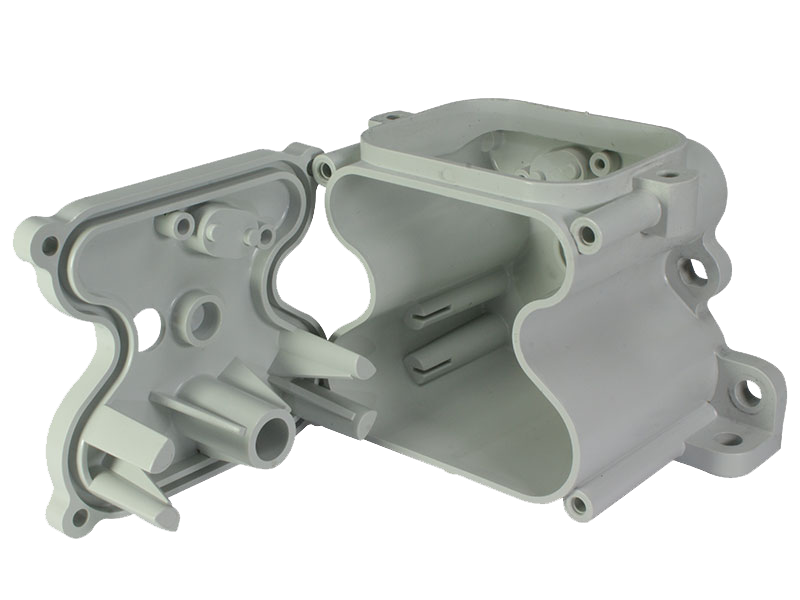

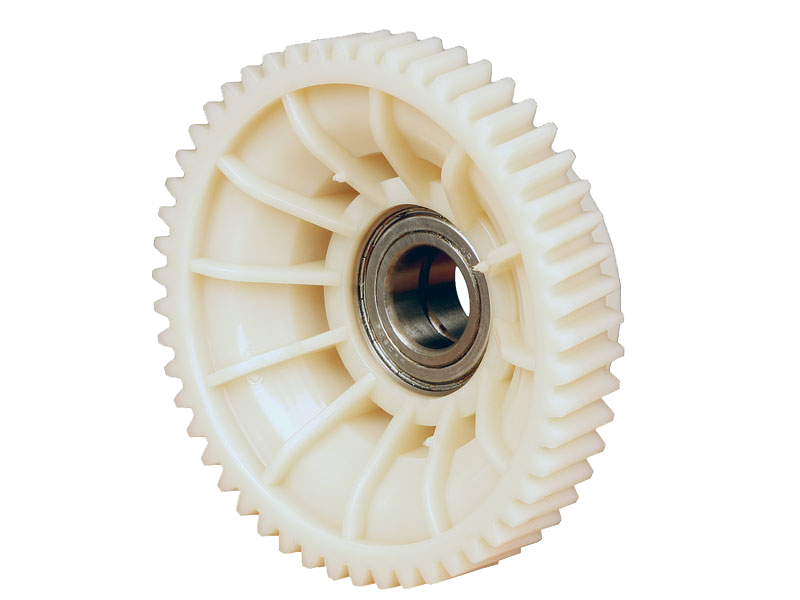

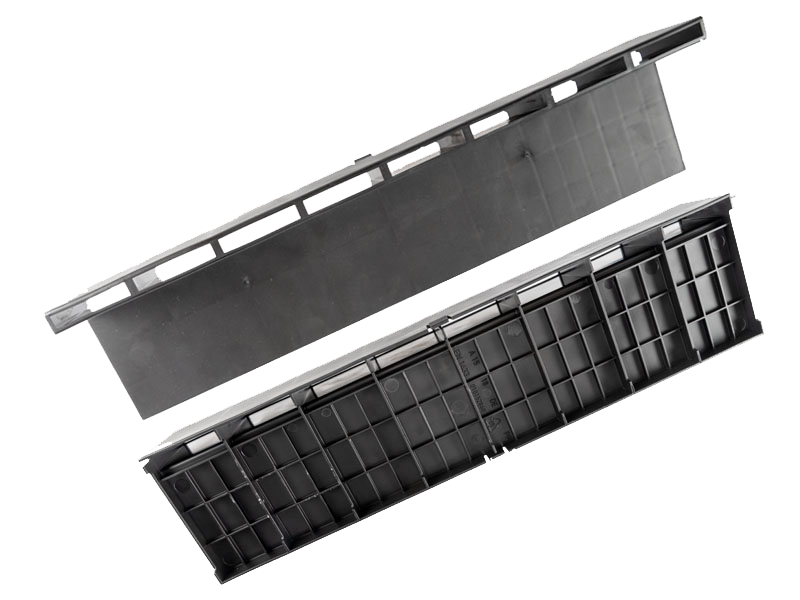

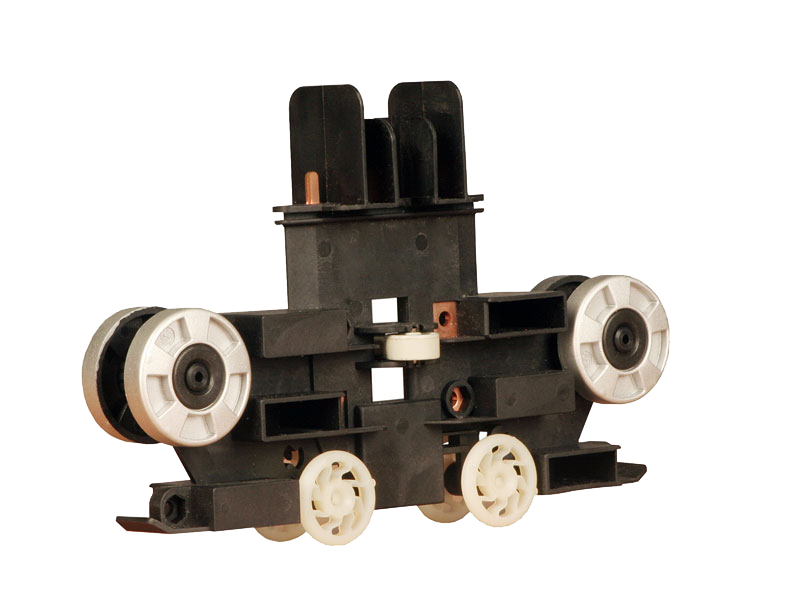

If you take a closer look at the samples, you will see, that none of the construction parts look alike. WPK places great emphasis on individual production. We produce high – quality items to meet the specifications of our customers.

Individual production depends on the drawing or the requirement of the construction component. Our technicians and engineers develop construction parts according to our customers’ demands. We are able to take over tools which have been built by other injection moulding companies as well. In this case we have to check, if the tools are ready for further use, or if we need to reconstruct them. In case of a reconstruction, we are going to optimise the tools and the cost – effectiveness.

Tool construction is an essential part of our production. With our modern in – house tool construction we are able to manufacture fully developed tools according to our customers’ requirements.

We are particularly interested in cost – effectiveness for both, the tool construction and the production of your plastic parts.

We are very flexible at plastic injection moulding. Shape, colour, material, quality and so on are factors which we adjust according to our customers’ demands.

We have 24 modern injection molding machines from Arburg and Battenfeld at our disposal for the production of injection molded parts.

We use these machines to produce more than 1,200 different plastic parts for various industries. Even finished parts with complex geometries and in almost any size can be injection molded in a single step.

Our modern injection moulding machines can achieve an injection weight of 1g to 2.8 kg, with clamping forces of 350 kN to 5,700 kN. All known thermoplastics are used as raw materials.

Thanks to advanced automation, for example with removal robots, and our state-of-the-art production site, we can guarantee you a high level of quality, reliability, process reliability and cost-effectiveness.

Further processing services such as conditioning, assembly, printing, hot stamping and painting are also part of our service.